Table of Contents

Pneumatic Atomization Technology

“Pneumatic nozzle” means mixing two things, usually air and water, but we can also use two liquids. Pneumatic nozzles, also called twin-fluid nozzles, are used in many places. They come in two types: internal and external mixing. Gas and liquid mix inside or outside the nozzle. The nozzle design decides if the liquid comes in by itself or with pressure, making different spray patterns. Pneumatic nozzles are great for spraying small amounts of liquid, but they work for larger amounts too. Different speeds of gas and liquid inside the nozzle make waves that cut the liquid flow, making tiny droplets. These speeds are key to spraying thick liquids with low pressure.

What is Atomization Technology?

Atomization involves breaking liquids into tiny droplets. It’s crucial for various applications. Methods include pneumatic, ultrasonic, pressure swirl, and rotary atomization. infectious disease.

Applications of Atomization Technology Across Industries

Atomization is vital across industries like manufacturing, agriculture, and medicine. For instance, in manufacturing, atomization is used for spray painting. In agriculture, atomization is essential for pesticide application. In medicine, atomization is utilized in nebulizers. covid-19 data.

Benefits of Using Atomization Technology

Atomization improves efficiency and effectiveness, such as achieving better coating and reducing waste. It also offers environmental benefits by lowering solvent use and enabling precise application. advanced atomization technologies. John Hopkins University.

Common Types of Atomization Systems

Pneumatic atomization involves mixing gas and liquid to produce fine droplets. Ultrasonic atomization uses ultrasonic waves to break liquid into droplets. Pneumatic atomization offers precise control but may not be suitable for thick liquids. Ultrasonic atomization is efficient but may be limited in scale. Other methods like pressure swirl and rotary atomization are also used, each with its advantages and disadvantages. la crosse technology atomic clocks. public health.

Pneumatic nozzles offer a lot of advantages:

- Very fine droplets are generated

- Precise volume flow control possible with consistently good atomization quality

- Hardly any liquid pressure is required to atomize finely

- Substances with a viscosity of up to 1,000 mPa·s can be atomized

Pneumatic atomization

Pneumatic nozzles are capable of generating almost any spray pattern:

- Flat fan

- Full cone

- Hollow cone (very rare)

Pneumatic flat spray atomization

Pneumatic flat fan nozzles create a flat spray with very small droplets and wide spray angles up to 80°. They’re perfect for tasks needing fine droplets and a broad, straight impact. See You More Info Atomization Technology.

They’re used for things like:

- Making the air wet and cool

- Keeping assembly lines damp

- Applying coatings

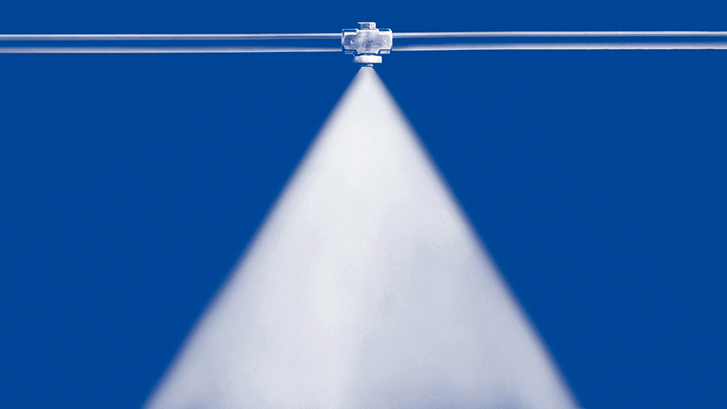

Pneumatic full cone atomization

Full cone pneumatic atomic technology nozzles are liked for jobs needing a circular hit or more spread. Usually, they make a slim full cone with a 20° to 30° spray angle. You can get wider sprays using nozzles with many holes.

They’re used for:

- Making air damp

- Cooling things

- Putting on thick stuff like oils

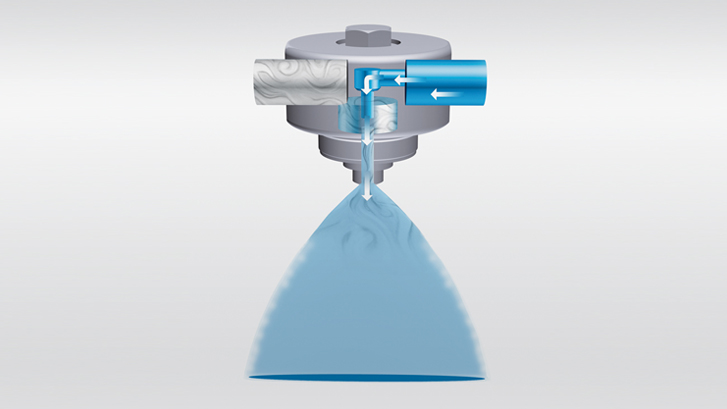

Mixing of fluids

Air or gas helps break up the liquid into tiny drops more. This mixing can happen inside or outside the nozzle.

Inside mixing is better for water, thin liquids, or ones without bits.

Outside mixing is good for thick liquids that might clog the nozzle. We use low liquid pressures with this type.

External mixture

In external mixing pneumatic nozzles, gas, and liquid mix after coming out of the nozzle. Liquid comes out through a hole in the middle, with gas streams around it. The fast gas flow breaks the liquid into tiny drops. La Crosse technology atomic clock with temperature.

These nozzles are great for thick liquids, but they have limits:

- They only make a narrow full cone spray.

- To get a flat spray, you need two air holes facing each other. Some nozzles, like the series 176 (ViscoMist), do this. They break the liquid into drops in two steps:

- The full jet of liquid gets partly broken by air.

- Two small air holes at the nozzle’s tip make the flat spray.

- These nozzles can’t handle big flows because of how they’re built. They’re better for spraying small amounts of liquid.

- La crosse technology curved digital atomic wall clock.

Internal mixture

With internal mixing pneumatic nozzles, the liquid and gas mix inside the nozzle. This makes the spray finer when it comes out.

Compared to external mixing, internal mixing is easier to control. It can spray both small and big amounts of liquid.

But, internal mixing isn’t good for thick liquids. You need to pick the right mix of air and water, and it’s best not to use high pressure.

Final Thoughts

Pneumatic Atomization Technology offers a versatile solution for generating fine droplets in various applications. Whether through internal or external mixing, the technology provides precise control over spray patterns and volume flow, catering to different viscosity levels. Understanding these principles can greatly enhance efficiency and effectiveness in atomization processes across indu

FAQs:

What is the atomization technique?

The atomization technique involves breaking liquids into fine droplets, often achieved through methods like pneumatic or ultrasonic atomization.

What Is the concept of atomization?

Atomization is the process of converting a liquid into tiny droplets, enhancing its surface area and dispersibility.

What is atomization used for?

Atomization is used in various industries for tasks like spray painting, pesticide application, and medication delivery, ensuring precise and efficient distribution of liquids.